There are four main electroplating methods in the production of PCB printed circuit boards: finger plating, through-hole plating, reel-linked selective plating ...

A: Focus on the process capability range. When choosing a PCB manufacturer, try to choose a circuit board manufacturer with a wide range of processes and strong...

In daily life, for the solder mask color of PCB circuit board, green is the most seen. With the progress of the times, various ink colors such as red, blue, pur...

Before using the mask, the PCB circuit board panel must be clean and free from oxidation. This is usually done using a chemical solution or scrubbing with a sus...

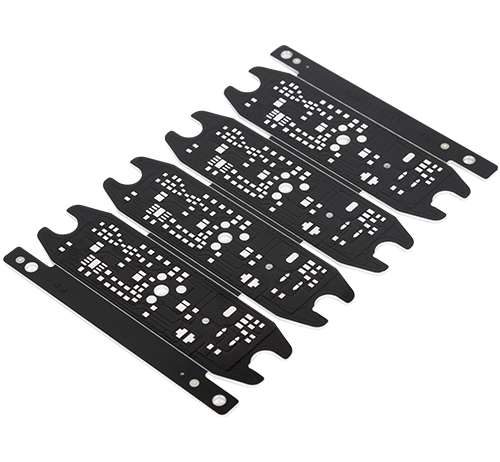

The number of layers is generally multi-layer boardThickness: 2.5mm or moreLarge PCB aspect ratioBig board sizeThere are few outer layer traces, and most of the...

The process first requires positioning holes for positioning and punching. Electroplating the first drilled PCB, sealing the positioning holes with dry film bef...

The main advantages of laser drilling, they include:No Drilling Vibration - Since laser drilling is a non-contact process, it does not cause any drilling vibrat...

The importance of laser drilling is increasing as the use of HDI technology in PCB fabrication designs requires the use of microvias. These smaller sized holes ...

Choose a material with a low dielectric constant (Dk): Since the Dk loss increases proportionally with frequency, it is necessary to choose a material with as l...