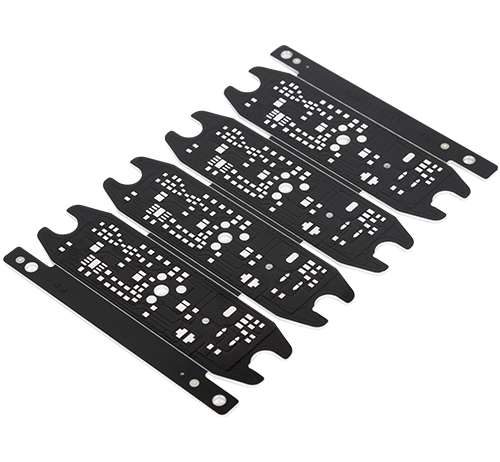

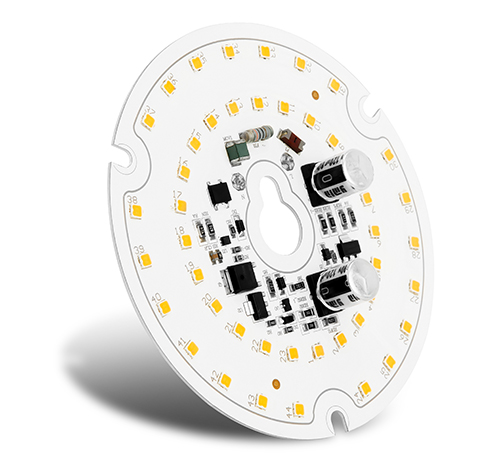

We can provide various MCPCB with good thermal conductivity, which are widely used in LED lighting and auto lights.

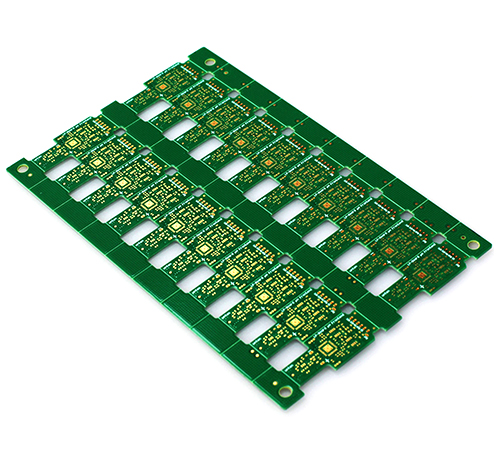

We can manufacture double layer and multiple layer FR4 board up to 32 layer, and other HDI, Flex-rigid PCB.

PCB Assembly offers a full service for your complex and mixed technology low to medium volume from prototype to production.

We are professional on MCPCB, PCB and PCBA solution

mcpcb,pcb,pcba

HYY was established in 2009

Factory area of 8500 square meters

More than 350 staff

Monthly output of 38,000 square meters

Play Video

Play Video

Professionalism comes from four dimensions of delivery standards

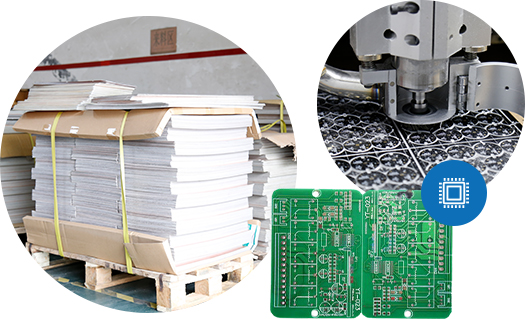

Raw material

collection standard

Technical Application

Standards

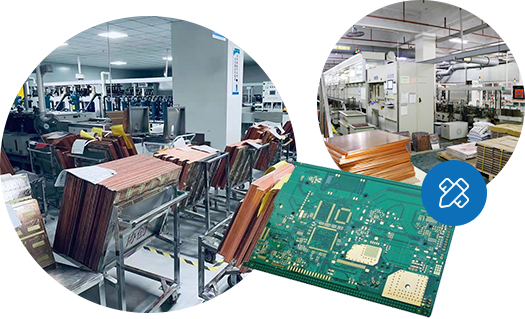

Customized production

standard

Environmental Control Quality

Inspection Standards

The collection of product raw materials is far higher than the industry production quality inspection standards, and the major materials are all listed companies in the industry. It has a perennial strategic supply relationship with well-known suppliers in the sheet metal industry: Shengyi Technology, Kingboard Technology, and Jinan Guoji. Copper materials are purchased from Jiangxi Copper Group, and tin raw materials are made of Yunnan tin. The procurement of raw materials is transparent and the quality is guaranteed.

A team of managers and technicians with more than ten years of PCB experience, involving more than ten industry customizations such as digital, communication, MP4, medical equipment and GPS, has the ability to deeply optimize the samples given by customers, and create more cost-effective application products for customers. .

We have professional circuit board production lines, adopts the full-process mechanized production process, and customizes double-sided circuit boards, four-layer circuit boards, six-layer circuit boards and multi-layer circuit boards according to customer industry needs. The product delivery ability is strong. According to the customized production volume, the average delivery time of the product is 8 days. And set up an emergency production delivery system, 4 days to achieve rapid product delivery.

Products our comany has passed pass the US UL certification, quality system certification ISO9001, ROHS, REACH environmental certification. The first inspection is carried out on each process of the production line to ensure the delivery quality of the product line. Electroplating has a chemical laboratory, which can accurately monitor and record the daily parameters of chemical treatment. Each batch of boards has a hole copper thickness gauge to test the holes for compliance. Batch products are customized and fully tested and shipped. After full inspection by FQC, the products are packaged and put into storage to ensure the quality of product delivery in an all-round way.

Mainly exported to European, Southeast Asia and USA

Europe

North America

China

Southeast Asia

Here you will see the latest news

FAQ