Time:2023-03-20 Visit:

The automotive electronic market is the third largest application area of PCB after computer and communication. With the car mechanical products in the traditional sense, the automotive has gradually evolved and developed into a high -tech product of intelligent, informatized, and electromechanical integration. The application of electronic technology has been widely used in automobiles. Safety systems, information systems, and in -car environmental systems have adopted electronic products without exception. The automotive market has obviously become another highlight of the electronic consumer market. The development of automotive electronics has naturally driven the development of automotive PCB.

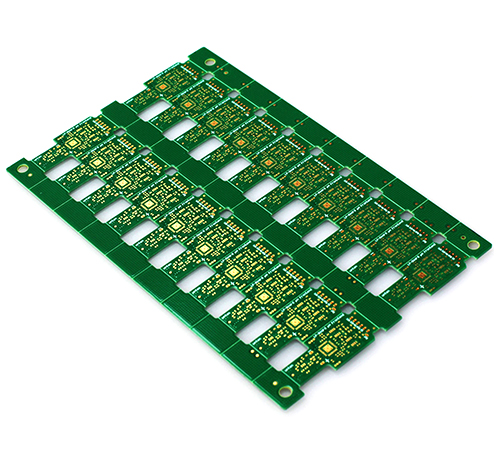

In today's PCB key application objects, the PCB of automobiles occupies an important position. However, due to the special working environment, safety and large current requirements of the car, it has high requirements for the reliability and environmental adaptability of PCB, and the types of PCB technology involved are also wide. This is a PCB enterprise. Challenges; for manufacturers who want to open up the car PCB market, they need to do more understanding and analysis of the new market.

PCB for cars specially emphasizes high reliability and low DPPM. So, does our company have technical and experience accumulation in high reliability manufacturing? Is it consistent with future product development direction? In terms of process control, can it be well good In accordance with the requirements of TS16949? Do you have achieved low DPPM? These must be carefully evaluated. When you see this seductive cake and blindly enter, it will cause harm to the company itself.

Some of the representative production of some representative production of PCB enterprises in the test process will provide some special methods in the test process to provide PCB colleagues for reference:

1. Second test method

Some PCB manufacturers adopt the "secondary testing method" to improve the rate of first high -voltage electrical breakdown defect board.

2. Bad board anti -dumb test system

More and more PCB manufacturers have installed the "Good Board Labeling System" and "Bad Board Cases" in the optical board testing machine to effectively avoid human missing. The good board marking system marks the test machine to the testing PASS board, which can effectively prevent the test board or bad board flowing into the customer's hands. During the test, the bad board prevention box is to test the signal of the output box of the output box when the PASS board is tested. On the contrary, when the bad board is tested, the box is closed to allow the operator to place the tested circuit board correctly.

3. Establish a PPM quality system

At present, PPM (PARTSPERMION, the defect rate of one million points) has been widely used in PCB manufacturers. Among the many customers of our company, the application and achievement that it has applied and achieved by Singapore's Hitachichemical is worthy of reference. In the factory, more than 20 people are responsible for the statistical analysis of the quality abnormal quality of the online PCB and the quality of PCB quality abnormal return. The statistical analysis method of SPC production process is used to classify the statistical analysis of each bad board and the defective board returned by each piece, and analyze which production process will be used in combination with auxiliary tools such as microclics. According to statistics, it is destined to solve problems in the process.

4. Comparison test method

Some customers have different batches of PCB adopt two different brands of models for comparative tests and track the corresponding batch PPM conditions to understand the performance conditions of the two test machines, so as to choose a test machine with better performance to test the PCB of the car.