Time:2023-02-16 Visit:

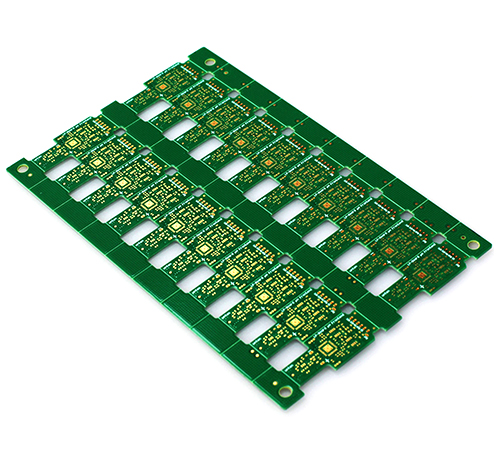

At first glance, regardless of the internal quality of PCB, the surface is almost the same. It is through the surface that we see differences, and these differences are the key to the durability and functions of PCB in the entire life.

Whether in the manufacturing assembly process or in actual use, PCB must have reliable performance, which is very important. In addition to related costs, the defects in the assembly process may be brought into the final product by PCB, and it may fail in the actual use process, resulting in claims. Therefore, from this point of view, it can be said without saying that the cost of a high -quality PCB can be ignored.

The consequences of such faults are unimaginable in the market of all market segments, especially in the market in key applications.

When comparing the price of PCB, you should keep in mind these aspects. Although the initial cost of reliable, guaranteed and long -lived products is high, it is still worthwhile in the long run.

14 most important features of high reliability circuit boards

1. The copper thickness of the hole wall of 25 microns

Benefits: Enhance reliability, including improving the expansion resistance of the Z axis.

Risks not to do so

The electrical connectivity problem (inner layer separation, the fracture of the hole wall) in the process of blowing the holes or qi, or the fault may occur under the load conditions in actual use. IPCCLASS2 (standards used by most factories) requires 20%less copper plating.

2. No welding repairs or cut -the -line repairs

Benefits: The perfect circuit can ensure reliability and security, no maintenance, no risk

Risks not to do so

If the repair is improper, the circuit board is broken. Even if you repair the "proper", there will be risk of failure under the load conditions (vibration, etc.), which may fail in actual use.

3. The cleanliness requirements beyond the IPC specification

Benefits: Increasing PCB cleanliness can improve reliability.

Risks not to do so

The residues and welded concentrations on the circuit board bring risks to the anti -welded layer. Ion residue will cause welding surface corrosion and pollution risk, which may cause reliability problems (bad solder joints/electrical failures), and eventually increase the occurrence of actual failure Probability.

4. Strictly control the service life of each surface treatment

Benefits: welding, reliability, and reducing the risk of moisture invasion

Risks not to do so

Because the surface treatment of the old circuit board will change in gold phase, welded problems may occur, and the tide invasion may lead to problems such as layers, inner layers, and pores in the assembly process and/or actual use. Essence