Time:2022-09-14 Visit:

How to prevent the precision PCB circuit board from bending and warping when it passes through the reflow oven?

We all know that precision PCB boards can easily bend or warp as they pass through a reflow oven. So how to avoid this, here are some suggestions that hopefully will help.

1. Reduce the effect of temperature on the gravitational force of the circuit board

Since "temperature" is the main source of attraction in the board, as long as the temperature of the reflow oven is lowered or the heating and cooling rate in the reflow oven is slowed down, board bending and board warping can be prevented. decrease very much. However, other side effects may occur, such as solder shorts.

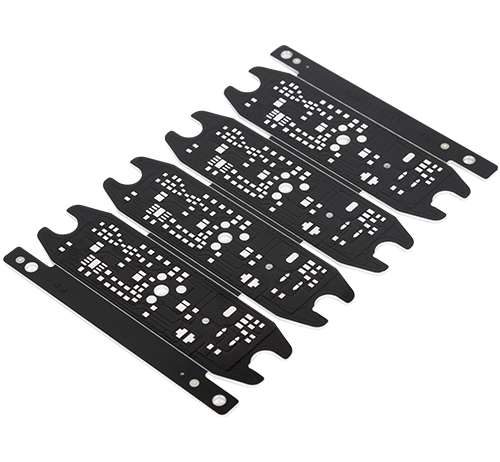

Multilayer PCB printed circuit board circuit board production and processing

2. Use high Tg boards

Tg is the glass transition temperature, the temperature at which the material changes from a glassy to a rubbery state. The lower the Tg value, the faster the board starts to soften after entering the reflow oven, and the longer it takes to become soft gelatinous. The deformation of the precision PCB circuit board will of course be more serious. Using a higher Tg sheet can increase its ability to withstand stress deformation, but the price of the material is relatively high.

3. Increase the plate thickness

In order to achieve the purpose of being lighter and thinner, the boards of many electronic products have a thickness of 1.0mm, 0.8mm, or even 0.6mm. Such a thickness makes it difficult to prevent the board from deforming after passing through the reflow oven. Therefore, it is recommended that if there is no requirement for thinness and lightness, the board can use a thickness of 1.6mm, which can greatly reduce the risk of bending and deformation of precision PCB circuit boards.