Time:2022-08-26 Visit:

For some friends who are new to aluminum substrates, there are still doubts about the difference between aluminum substrates and PCB boards. Today, I will tell you this question in detail.

Aluminum substrate is a metal-based copper clad laminate with good heat dissipation function. A single panel is generally composed of a three-layer structure, namely a circuit layer (copper foil), an insulating layer and a metal base layer. PCB boards, also known as printed circuit boards, are the provider of electrical connections for electronic components.

PCB board is a big category, aluminum substrate is just one of them, it is designed according to the requirements of the PCB board. The aluminum substrate we generally call is a single-sided aluminum-based PCB board with good thermal conductivity, which is generally used in the LED industry. At present, the most commonly used LED aluminum substrate has two sides, the white side is used for soldering LED pins, and the other side shows the true color of aluminum. Generally, the thermal paste is applied first, and then it is in contact with the thermally conductive part.

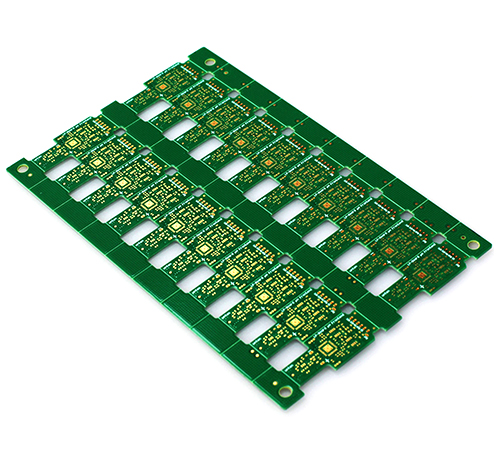

The most common PCB boards we are talking about are generally copper substrates. According to the number of layers, it can be divided into single and double layers and multi-layer boards. Compared with the aluminum base plate, one material is copper and the other is aluminum plate. Due to its special PP material, the heat dissipation effect of the aluminum substrate is better than that of the PCB board, and the price is relatively expensive.