Time:2022-08-09 Visit:

Dismantling method: For the dismantling of the integrated circuit, it is best for beginners to use a solder fan, move quickly along the peripheral pins of the chip with a hot air nozzle, heat evenly until the solder melts, and then clamp it down with tweezers. However, there are several points to pay attention to when using hot air: the hot air nozzle is 1 to 2mm away from the solder joint, and it cannot be directly connected to the corner chip pins, nor too far away. Do not blow continuously for more than 20 seconds, preferably not more than 3 times in the same position. For different welding objects, through trial and error, the appropriate temperature and air volume can be selected.

Generally, for chips with two rows of pins, you can also directly use an electric soldering iron to put enough tin on the two rows of pins to form a tin block, and then use the soldering iron to quickly heat the blocks at both ends of the tin and move them along all the pins. After the pins of the chip are all loose, the chip can be taken out with tweezers.

Weld both ends of some components such as chip resistors and capacitors: adjust the temperature of the soldering iron to 250-300 degrees Celsius (too high temperature will damage the components), first put tin on one end of the pad, and use tweezers to clamp the two sides of the component and Fixed on the pad, solder one end first and then the other end. Once you get used to it, you can no longer use tweezers. After tinning the pads on both ends, use a soldering iron to tin one end of the resistor. Because the resistance is too small, it will stick to the tip of the soldering iron. Quickly place it on the pad and melt the tin on both ends of the pad. Automatic alignment, welding is completed.

Removal method: Use a soldering iron to tin both ends of the component, and after the tin is completely melted, clamp it with tweezers.

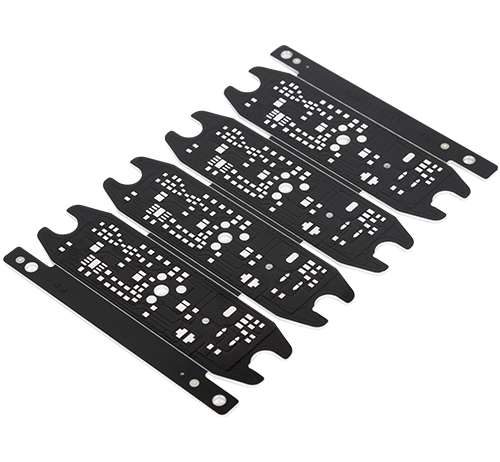

Welding of integrated circuits: For integrated circuit chips with many and dense pins, it is necessary to place the chip on the pad first, after alignment, melt it with a small amount of solder and then solder it on several pins on the chip, so that the chip can be Once it is properly seated, tin the other pins. After you are proficient, you can perform "drag soldering", that is, put tin on the pins on one side, then melt the solder with a soldering iron, and wipe off the remaining pins on one side. , the solder wire can flow after melting. Use the tip of the soldering iron to guide the flow of molten tin to the other pins to ensure that all pins are evenly tinned, and then use the tip of the soldering iron to scrape the excess tin along the pins. until the pins are no longer connected.