Time:2022-08-08 Visit:

The curve splitter tool is abnormal, and some nodes will remain and be drawn. However, in actual production, there are many problems with residual dust. In this case, the vacuum system should be checked. The carrier for the daughterboard is a hollow metal frame. There are pillars at the bottom to support the PCB. The position of the pillars is not reasonable. In the process of taking out the PCB, components may be scratched, so you need to pay attention.

The sub-board technology in PCBA production is shared here. In the next article, we will share the plug-in process in printed circuit board processing.

When the PCB board is thick or irregular in shape, the V-cut splitter cannot be used, only the automatic curve splitter can be used. The connection between the edge of the board and the PCB board can be punched, as shown by the arrow in Figure 2, or not, as shown in Figure 5 below. Using an automatic splitter requires programming, and engineers need to optimize the optimal tool path. During the sub-board operation, first put the PCBA into the carrier board and fix it, then put the carrier board and the circuit board into the automatic sub-board machine, and press the button to start the sub-board operation. Vacuuming and static elimination also work together during the depaneling process.

For PCBs with regular shapes and thin boards, the connection point between the edge of the board and the PCB generally adopts the V-groove method. In the beginning, the edge of the board is broken directly by hand or with tweezers. In this way, unpredictable stress will act on the PCB board, which is easy to cause cracking of components, and it is easy to draw lines at the position of the connection point on the edge of the board.

Later, it was developed to use a V-cut separator. As shown in FIG. The above problems can be effectively avoided. Just manually align the V-cut position of the plate with the lower blade of the splitter, step on the pneumatic switch, and move the upper round knife left and right to complete the splitting work. Efficient and labor-saving. The V-cut divider requires no programming, as long as the knife is sharp. However, since the board is held in place by hand, if the tool is not aligned with the position of the V-groove, it is possible to trim the wire near the V-groove. If the tool is not sharp, there may also be abnormal situations such as wire drawing after the board is divided. This type of knife can only chop straight edges.

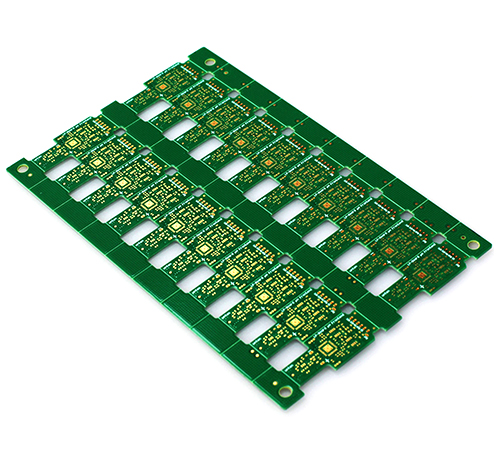

The PCB board is very small. In order to improve efficiency, the method of connectors is used in the production of PCBs. Depending on the size of the PCB, 2, 4, 6, etc. can be used. The very small board has 32 pieces. Make use of space as much as possible, as the edge of the cut is also important. This kind of small PCB is generally assembled with SMT and plug-in components, and the sub-board work is done after wave soldering. This type of board can be done with a linear divider or an automatic curve divider.

The size of the PCB is large, but it needs to be designed into an irregular shape for subsequent assembly. The excess part can only be cut off. This type of PCB can only be used with an automatic curve divider.

Customers have special requirements. The customer wants to measure whether the characteristic impedance of each batch of PCB boards meets the design requirements through TDR (Time Domain Reflectometer). They will ask for the PCB board to add a coupon. Such PCB boards need to be cut during the production process, and the corresponding batches will be sent to the customer for confirmation.

Printed circuit boards are often referred to as PCBs. Components on a PCB are called circuit board assemblies or PCBAs. Components on the board can be SMT components, plug-in components or assemblies. The last article shared the AOI (Automatic Optical Inspection) test site after PCBA (circuit board assembly) reflow soldering, and today shared the process after SMT - sub-board.

In the PCBA production flow chart, the sub-board process is marked as an option, and not all PCBs require sub-board. In order to assist SMT patches, plug-ins, etc., the board edges (process edges) added on both sides or four sides of the PCB board do not belong to the PCB board, and will be cut off after the PCBA production is completed. The process of cutting the edge of the board is called splitting. In the process of SMT placement, reflow soldering, AOI testing, etc., the PCB board runs automatically on the track, and the edge of the board can prevent the track from contacting the components on the board.