Time:2022-07-21 Visit:

The etching process is one of the basic steps in the process. To put it simply, the base copper is covered by the resist layer, and the copper that is not protected by the resist layer reacts with the etchant and is bitten off, and finally forms the design circuit pattern and pad. the process of. Of course, the etching principle can be easily described in a few words, but in fact the realization of etching technology is quite challenging, especially in the production of fine lines, the small line width tolerance requirement does not allow any errors in the etching process , so the etching result should be just right, not widening or overetching.

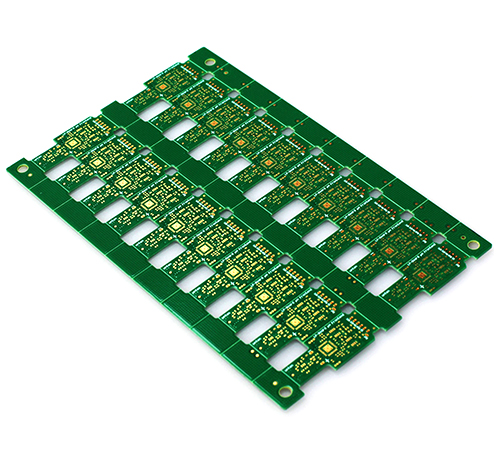

Detailed analysis of PCB vacuum etching technology, a detailed overview of principles and advantages

To further explain the etching process, PCB manufacturers prefer to use horizontal etching lines for production to achieve maximum production automation and reduce production costs, but horizontal etching is not perfect, and the "pool effect" that cannot be eliminated makes the board's The upper surface and the lower surface produce different etching effects. The etching rate of the edge of the board is faster than the etching rate of the center of the board. Sometimes, this phenomenon will cause a large difference in the etching results on the board surface.

That is to say, the "pool effect" will cause the lines on the edge of the board to be over-etched more than the lines in the center of the board, and even careful line correction (appropriately widening the line width on the edge of the board) to compensate for different etchings Rates also fail because the etch tolerances must be very finely controlled to achieve ultra-fine lines.

The change in the etch rate caused by this situation is quite significant. Located on the top of the circuit board, near the edge of the board, the etching solution is more likely to flow out of the board, and the old and new etching solutions are easier to exchange, so a better etching rate is maintained. In the center of the board, it is easier to form a "pool" situation, which restricts the flow of the etchant, and it is relatively difficult for the solution rich in copper ions to flow out of the board surface. The etching effect becomes poor. In practice, it is unlikely to avoid the "pool effect" because the chain-type horizontal drive rollers prevent the etchant from draining, resulting in a build-up of the etchant between the rollers, a phenomenon that is common in the production of larger boards. or ultra-fine lines, even if a relatively special production process control and compensation method is adopted, such as a spray system that can be independently adjusted horizontally and in the transfer direction, an oscillating spray pipe is added, and a corrective re-etching section is added. Wait, if there is no huge technical investment, this problem cannot be solved well, so to achieve the goal of avoiding the "pool effect", we have to go back to the starting point and start again.