Time:2022-07-07 Visit:

With the development of the electronic industry, the integration of electronic components is getting higher and higher, and the volume is getting smaller and smaller, and BGA type packages are generally used. Therefore, the lines of the PCB will become smaller and smaller, and the number of layers will increase.

Single-sided circuit board: It is generally believed that every time the production circuit board is increased or upgraded by a grade, it must be invested once, and the investment capital is relatively large. In other words, high-end circuit boards are produced by high-end equipment. However, not every enterprise can afford large-scale investment, and it takes a lot of time and money to do experiments to collect process data and trial production after investment. It seems to be a better method to do experiments and trial production according to the existing situation of the enterprise, and then decide whether to invest or not according to the actual situation and market conditions. This article describes in detail the limits of the width of thin lines that can be produced under normal equipment conditions, as well as the conditions and methods of thin line production.

The general production process can be divided into capping acid etching method and pattern plating method, both of which have their own advantages and disadvantages. The lines obtained by the acid etching method are very uniform, which is conducive to impedance control, and has less environmental pollution, but if a hole is broken, it will lead to scrap; the production control of alkali etching is relatively easy, but the lines are not uniform and the environmental pollution is also large.

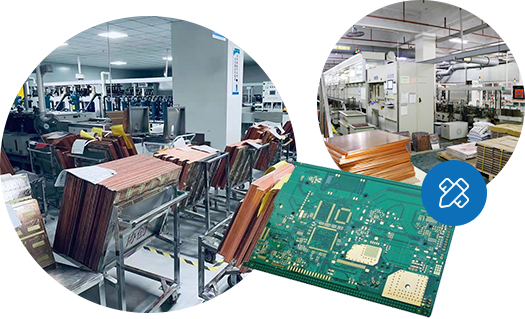

Precision Multilayer Circuit Board:

1. Refinement of conductors and miniaturization of through-holes in precision multi-layer PCB circuit boards have improved the requirements for processing equipment and process control levels of PCB circuit board processing plants, and also improved the overall management capabilities and employees of precision multi-layer PCB circuit board factories. A test of personal ability. The 6/6mil line width/line spacing production capability is not too difficult within the current equipment and materials, as well as the level of process control, and most PCB manufacturers can produce it. But the upgrade from 6/6 mil to 5/5 mil is a big leap, which makes many small and medium-sized manufacturers sigh and sigh. Seemingly simple, in fact, this requires circuit board processing manufacturers to have strong technical research and development capabilities and financial strength. Subject to the performance parameters of the exposure machine, the processing ability of the etching line, and the control ability of the whole process, etc., to achieve a 5/5 mil line and maintain a high yield, the overall strength of the factory needs to be supported. In the same way, the same is true for the production of finished product apertures of 0.3mm and below (holes below 0.3mm cannot be drilled by machine, generally laser drilling) precision multi-layer PCB circuits.

2. Others, such as copper-free holes, green oil falling off, immersion gold board BGA black PAD, solderability, etc., are common problems encountered by PCB manufacturers. However, as a special process product, PCB board integrates various traditional technologies and means such as machinery, electronic control, automation, chemistry, biology, ERP, cost, management, and environmental protection. It requires managers to exert great wisdom and employees to carry forward Only with great spirit can we strive to control every detail and maximize its quality control ability and level.