Time:2022-07-06 Visit:

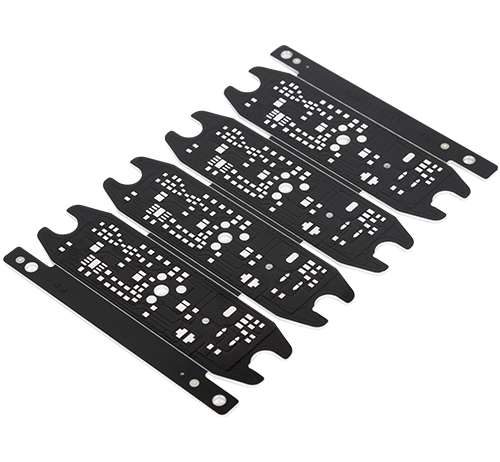

The quality control of the copper plating layer of the through-hole printed circuit board is very important, because the multi-layer or laminated board is developing towards high density, high precision, and multi-functionality. The requirements for strength and elongation are getting stricter and higher, so the quality control of through-hole printed circuit board plating is particularly important. Keyou Circuit is a company dedicated to PCB proofing and mass production, with high-precision single-sided / double-sided / multi-layer circuit boards (1-26 layers), thermoelectric separation copper substrates, multi-layer industrial control circuit boards, power pcb boards, medical circuits Board, security PCB board, communication PC board, automotive circuit board, instrumentation circuit board, military circuit board, composite busbar copper substrate, foldable metal substrate, FPC flexible and rigid board, etc., quality assurance, delivery on time, to sales An integrated high-tech enterprise.

To ensure the uniformity and consistency of the copper electroplating layer of through-hole printed circuit boards, in the copper electroplating process of high aspect ratio printed circuit boards, most of them are under the auxiliary action of high-quality additives, with moderate air stirring and cathode movement. Under the condition of relatively low current density, the electrode reaction control area in the hole is enlarged, and the effect of electroplating additives can be displayed. In addition, the movement of the cathode is very beneficial to the improvement of the deep plating ability of the plating solution, and the plated parts are When the degree of polarization increases, the formation speed of the crystal nucleus and the growth speed of the grain during the electro-crystallization process of the coating compensate each other, so as to obtain a high-toughness copper layer. Of course, the setting of the current density is determined according to the actual plating area of the printed circuit board to be plated. From the analysis of the principle of electroplating, the value of the current density must also be related to the main salt concentration, solution temperature, additive content, stirring degree and other factors of the high-acid low-copper electrolyte. In short, it is necessary to strictly control the process parameters and process conditions of electroplating copper to ensure that the thickness of the copper plating layer in the hole meets the technical standards.