Time:2023-04-10 Visit:

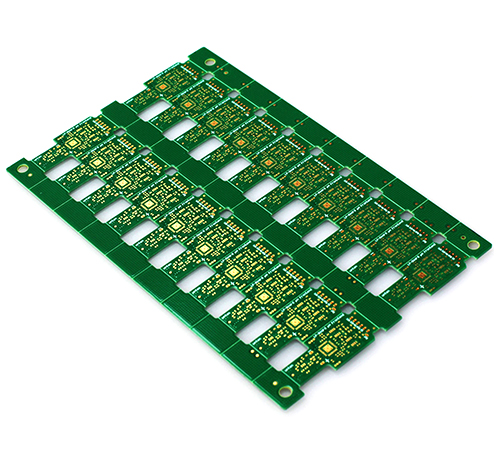

PCB is one of the indispensable components of electronic devices. It appears almost in each electronic device. In addition to fixed various parts of large and small parts, the main function of PCB is to connect various components electrical. Because the raw material of the PCB board is a copper -covering board, there will be a copper throwing phenomenon during the production of the car line board, so what are the reasons for the car circuit plate?

1. The design of the PCB line is unreasonable. The detailed lines of the thick copper foil will also cause the line to etch excessively and shake the copper.

2. Excessive etching of copper foil. The electrolytic copper foil used on the market is generally single -sided galvanized (commonly known as gray foil) and single -sided copper plating (commonly known as red foil). Common copper shampoo is generally galvanized copper above 70um or more Foil, red foil and gray foil below 18um basically have not seen batch -shaped copper.

3. Local collisions in the PCB process, and the copper wire is separated from the substrate from the external mechanical force. This adverse manifestation is adverse positioning or fixed directionality, and the copper thread will be distorted obviously, or scratches/impact marks in the same direction. The copper threads are peeled to see the copper foil surface. You can see that the color of the copper foil surface is normal, and there will be no poor side erosion.

4. Under normal circumstances, as long as the pressure plate is more than 30min, the copper foil and semi -solidified chip are basically combined with complete combination, so the pressure blending generally does not affect the combination of copper foil and substrate in the layer pressure plate. However, in the process of layer pressure plates and stacking, if PP pollutes, or damage to the hair surface of copper foil, it will also cause the lack of combination of copper foil and substrate after layer pressure Said) or sporadic copper threads fall off, but the peeling strength of the copper foil near the tank line will not be abnormal.